about us

uniqueness

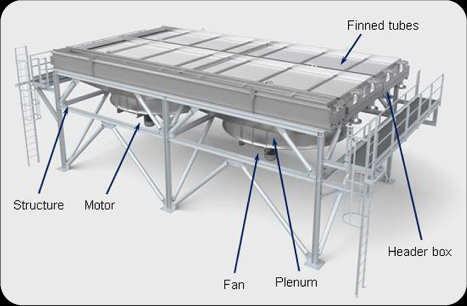

A Petronas licensed Bumiputra company and is owned and managed by a group qualified and experienced professionals. Was established as an Engineering Consultancy company providing consultancy services for Pipeline, Drilling, Electrical and Turnaround Project Management. Our principal activity is mainly of Airflow Improvement & Optimisation for Air Cooled Condenser and Air Finned Cooler services to Oil & Gas industry for Malaysia and Asia Pacific region.

View Profile

Mission

Our mission is to be an environmentally conscious, fiscally

responsible, well managed for-profit engineering company that

reinvests for future growth and development.

Our mission is to innovate and fully understand the problem or

opportunity. We will remain open minded and explore new

possibilities that lead to effective solution.

Our mission is to build and maintain alliances with those that

share our interests, can contribute to and participate in our

success. We believe in education, enrichment and development. We

will foster relationships that integrate the talent, interests and

goals of all our co-workers.

We focus on achieving this objective while maintaining the highest

quality products and services.

Vision

We will strive to be a leading solution provider within the industry and will be a quality organization of entrepreneurs committed to growth, opportunity and profit as well as community enrichment.

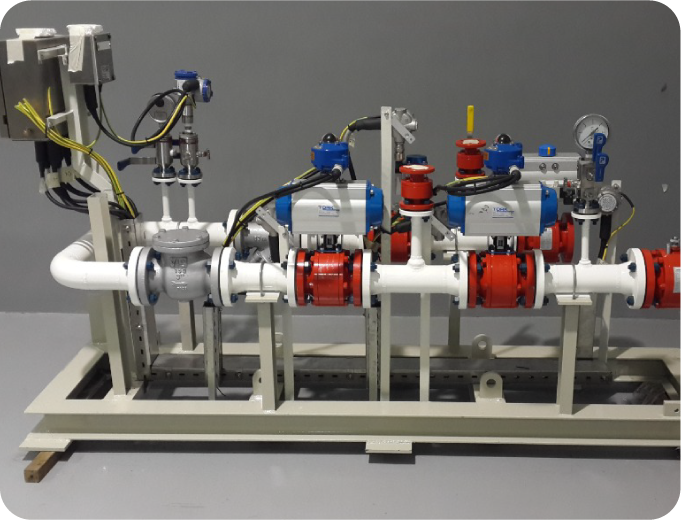

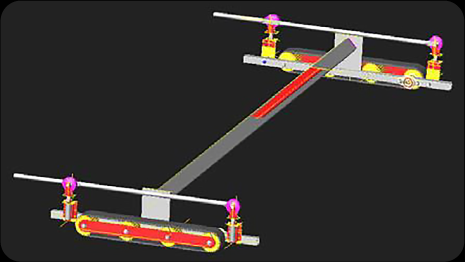

Wrong pitch angle

Wrong pitch angle

Correct pitch angle

Correct pitch angle

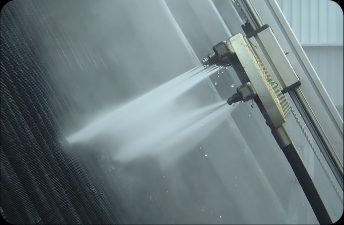

High pressure water beam penetrates through the bundle

High pressure water beam penetrates through the bundle

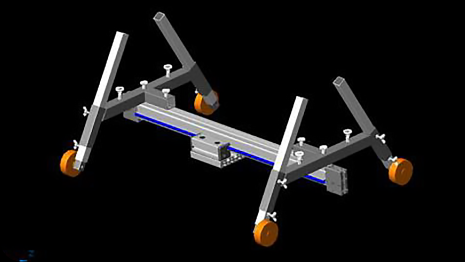

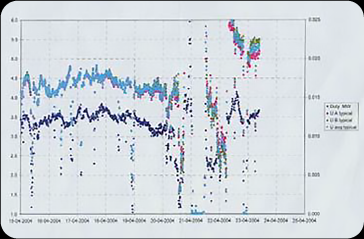

20% - 25% airflow improvement ‘the product flow increased

as the product temperature decreased

20% - 25% airflow improvement ‘the product flow increased

as the product temperature decreased